Logistics Division: VIEROL AG Logistics Centre

We supply our quality products to more than 125 countries. This is only made possible by an outstanding logistics structure.

An excellent data management system allows us to provide a particularly fast delivery: orders received by 17.00 Monday to Thursday and by 16:30 on Fridays reach their recipients in Germany the next morning, on weekdays, and in Europe within 48 hours.

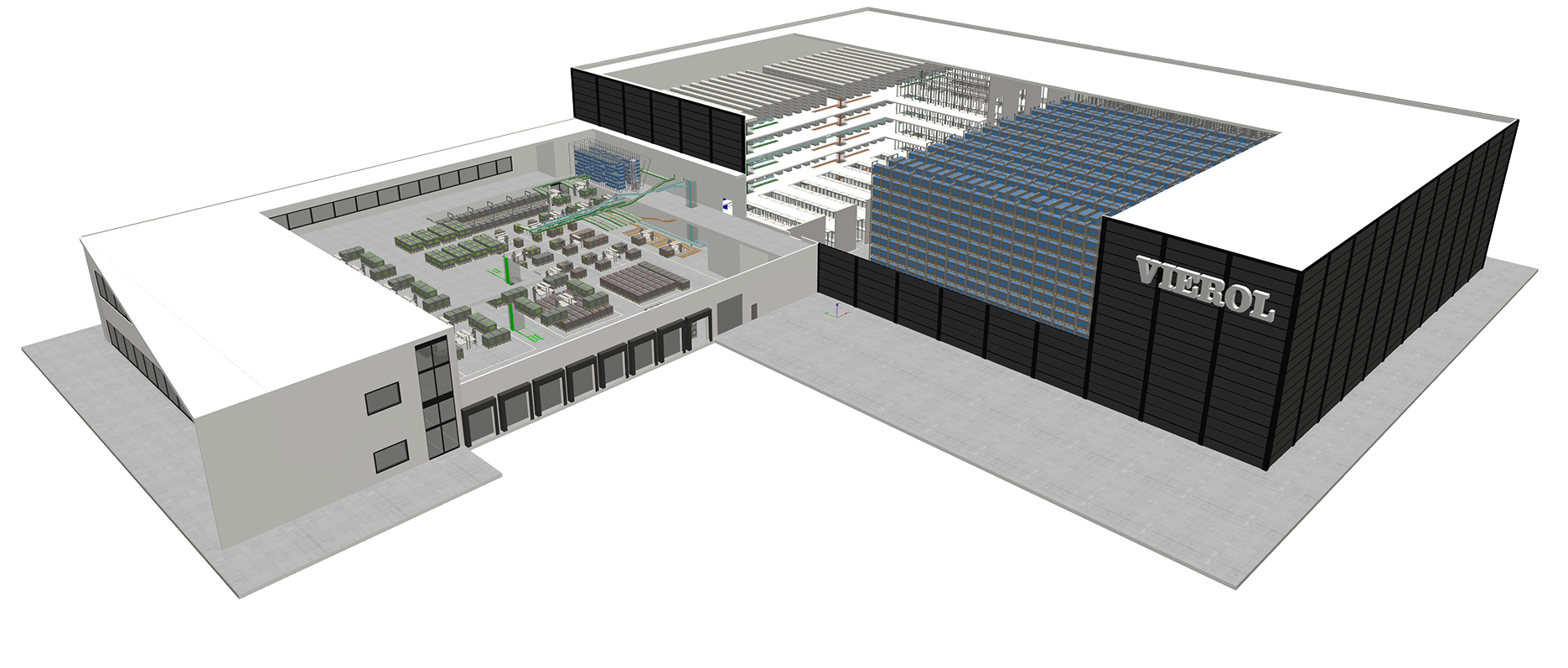

Logistics centre WERK II

After only one year of construction, we opened the new logistics centre WERK II in 2021. Modern logistics concepts, expanded storage capacities and a high degree of automation will ensure increasing efficiency of the workflows in the future in the supply of spare parts to global trade customers. The new logistics centre is located on a 20,000 m² site – only 600 metres away from the existing warehouse. WERK II is a clear commitment to the Rastede location and goes hand in hand with a significant improvement in the availability of goods and on-time delivery to customers.

Facts & Figures - WERK II

Occupancy in 2022centrally located in the industrial estate at the Oldenburg-Nord motorway junction in Rastede

Property: 19,883 m²

Hall space

Hall 1: 6,696 m²

Hall 2: 2,593 m²

Office and social rooms: 576 m²

Total area: 9,865 m²

Storage areas

Narrow-aisle high-bay warehouse: 12,600 storage locations

Cleat storage: Pallets: 969 storage locations

Additional level for cartons: 969 storage locations

Shelf storage: 91,247 storage locations

Automatic small parts warehouse (AKL): 480 bins

Outgoing goods racking: 378 storage locations

Conveyor technology - WERK II

Total length of the conveyor line: 580 mAutomatic small parts warehouse (miniload; consolidation buffer): 480 bins

Stroke of the 4 vertical conveyors: 12.8 and 7.0 m respectively

Speeds of the system

Totes on track: 0.6 m/s

Vertical conveyor: 2.0 m/s

stacker crane AKL: 4.0 m/s

Performance

Container conveyor system for incoming goods: 424 containers/h

Tote conveyor system goods issue: 828 totes/h

Pallet conveyor system: 63 pallets/h

Energy efficiency

The innovative energy concept includes a complete power supply from renewable energies. The building’s own environmentally friendly electricity is generated by means of a modern photovoltaic system, while the building’s own combined heat and power plant generates additional electricity and heat by means of a biogas plant. An intelligent ventilation concept with heat recovery and lighting exclusively with LED lights round off the sustainable concept.

Facts & Figures - WERK I

- acquired in January 2006

- central location at the Oldenburg-Nord motorway junction

- 12,500 m² warehouse

- modern shelving

- approx. 30,000 storage locations

- VIEROL Academy completed in 2018 as a training and presentation centre

Fuel depot WERK I

In 2016, the existing central warehouse at the Oldenburg-Nord motorway intersection was expanded. The newly created operating materials warehouse offers 420 storage spaces on an area of 325 m². Since then, the logistics centre has had the capacity to store around half a million litres of high-quality VAICO special oils as well as operating fluids and antifreeze MADE IN GERMANY.High-quality VAICO transmission, engine and hydraulic oils as well as antifreeze products are stored. This means that the complete range is available directly from stock.

The 2,500 m² warehouse extension provides additional storage space for over 2,000 pallets and creates volume for a further 50 containers.